OUR APPROACH

Technology alone doesn’t make our products—our challenger spirit and uncompromising craft do. By questioning conventions and perfecting innovation, we strive to put the soul into every lens and camera. Sigma’s high-performing lenses and cameras are proof of that. This challenger spirit and craft are embodied in our engineers’ exploration of new technologies and our skilled workers’ relentless refinement of the final product. They collaborate across departments, transforming ideas into reality through the synergy of their diverse skills and technologies. Making a Sigma product is not a rigid, standardized process—it’s dynamic, requiring constant creativity and dialogue. When the technology for an idea doesn’t exist, we invent it.

BEYOND DISCIPLINES

Sigma focuses on three key areas: development, manufacturing, and services. We design camera optics, bring them to life at our Aizu factory, and provide unique services like lens repair. Together, these form the foundation of Sigma’s offering. Our lenses and cameras cannot be created within the confines of isolated disciplines. They are born from inspirations and ideas that emerge through the collaboration and integration of diverse specialized fields.

Additionally, by handling every process—from research and development to manufacturing and after-sales service—we accumulate a wealth of expertise and experience. This collective wisdom, in turn, drives the development of new ideas and solutions.

SMALL OFFICE, BIG FACTORY

Our offices spark big ideas, and our factory turns them into high-quality products. The process can move quickly, beginning with concepts for lenses we want to create or innovations we believe could push photographers' creativity in new directions. Once we’ve figured out how to prototype them, we bring them to life using our advanced manufacturing technology in Aizu.

Our approach requires the integration of human thought and technology, and this balance is integral to our philosophy. Over the years, this exchange between humans and machines has become increasingly refined and seamless. That’s the advantage of having all research, development, production, and assembly in one place—Aizu, Japan.

STAYING VERTICAL

AN INTEGRATED SUPPLY CHAIN

Since our inception in 1973, Sigma’s production system has been entirely based in Japan. Unlike most production chains in today’s globalized world, we produce and tailor all components either at our own factory in Aizu or in collaboration with local businesses in the Tohoku region. This unique setup stands apart in an industry that predominantly focuses on sourcing the cheapest parts from around the globe. And it works. Having been in place for over five decades, it ensures the high level of quality and innovation in our lenses and cameras.

Our one-location production system provides other competitive advantages. Direct, face-to-face communication ensures speedy and meticulous product development. And since the same people are consistently involved in our manufacturing processes, they continuously gain experience, knowledge, and know-how, from which new innovations can spring.

Money alone cannot buy these merits. They require a holistic, intangible understanding that goes beyond mere products and services. We consider them our greatest, most irreducible asset. That is why our domestic, fully integrated production system is so important to us.

Introduction

At Sigma, we insist on the highest possible manufacturing quality for each of our products.

Our motivation, as ambitious photography enthusiasts, is our heartfelt understanding for the passionate photographer and our deep sympathy for their mission to record and to express themselves.

We would like to introduce you to a standard of quality unattainable by a mere emphasis on efficiency and productivity, by sharing a few select vignettes from our manufacturing factory in Japan's Aizu prefecture.“Like water through a river”

- a sentence from Michihiro Yamaki, Sigma's original founder.

Whenever Mr. Yamaki visited the factory in Aizu, he made sure to confirm whether all operations during the production process were running smoothly.500 different models

There currently is no one unifying mount that works for each interchangeable camera mount system in the market. As a result, according to the model numbers of our manufacturing plan, we produce about 500 different lens variations at our Aizu factory.

Tokyo and Aizu

Sigma's spherical lenses are manufactured with an impeccably accurate surface roughness (i.e.., the degree of roughness compared to an ideal, smooth surface) of merely 2 micrometers. If we created a lens with a diameter of 300 kilometers -- the distance between Tokyo and Aizu -- the largest bulge would measure less than 2 centimeters.

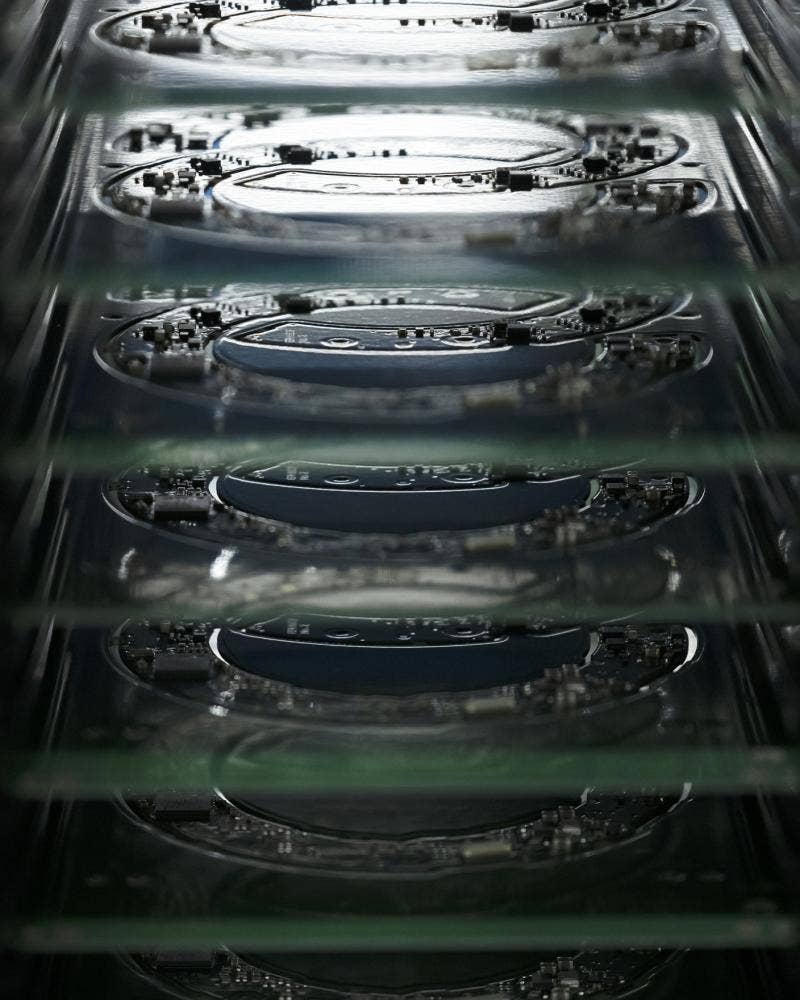

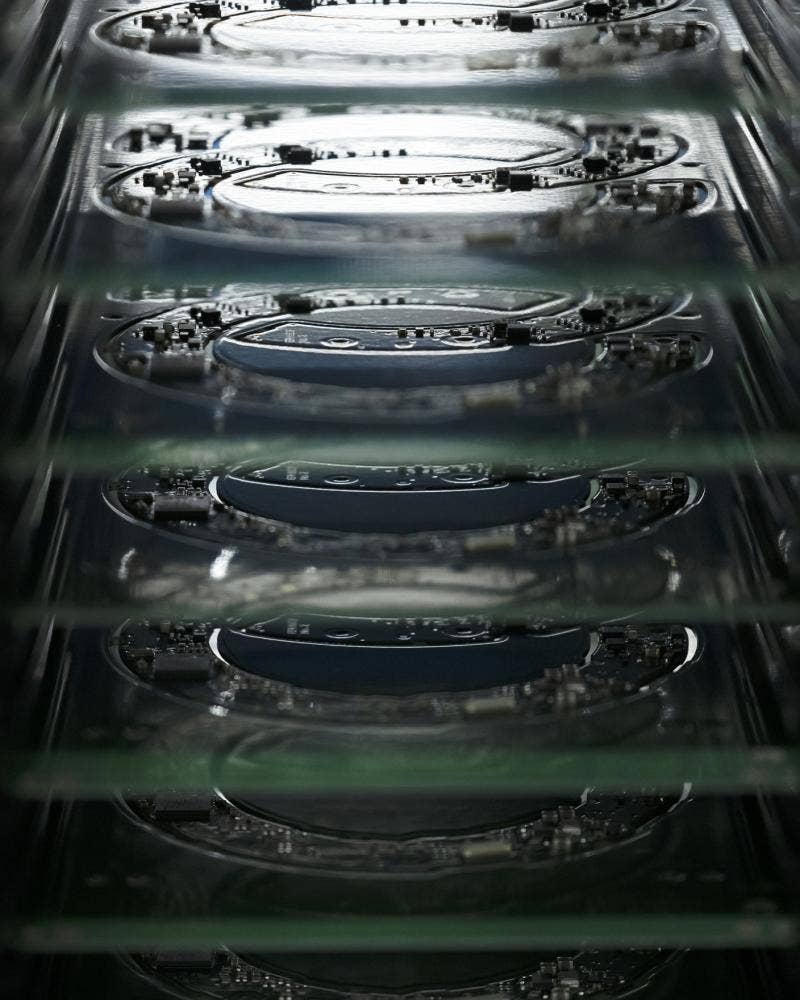

From 10mm to 198mm

The largest single lens manufactured by Sigma is the front element of the APO 200-500mm F2.8 EX DG, with a diameter of 198mm. Applying the lens coating is an eight hour long process.

In contrast, the smallest single lens used in any of our products is the 7th element in the 8-16mm F4.5-5.6DC HSM zoom lens: it measures only 10mm.Three minutes, three letters

With the introduction of Sigma GLOBAL VISION in 2012, we have started engraving a three-digit code onto each of our lenses. In addition to clarifying the release year of each model, we hope the number helps our customers develop a bond with their product, a little like vintage wine.

The three letters atop each model are engraved using a very small end mill. The process is undertaken with great care and requires around three minutes.Bayonets without compromise

Our brass bayonets are manufactured with thick chrome platings, to ensure a quality finish without any scratches.

We have adopted trivalent chromium into our production process as soon as it became industrially possible. The trivalent chromium perfectly answers our needs to create plating film without surpassing 0.5 micrometers in thickness. Abandoning the highly toxic hexavalent chromium allows us to be more considerate of our workers' health and our factory's effects on the environment."Five more micrometers"

When designing and producing molds, the mold's finishing is reviewed in thorough detail. For the fine-adjustment process, we commonly work in units of micrometers (0.000'001m).

A1 with data of all shipping lenses

Each individual lens that has been shipped since the introduction of Sigma GLOBAL VISION in 2012 has been measured and quality controlled with the A1, Sigma's very own MTF measuring device. Precise measuring data for each individual lens is stored in our facility in Aizu..

Painted by hand

The components of our products that cannot satisfyingly handled by machines receive their finishing touches by hands. For example, the complex inner structure of the filter holder socket of our 500mm DG OS HSM | Sports lens is hand-painted, piece-by-piece, by a worker in our Aizu factory. Another example are the tripod mounts of our large-aperture lenses: each of them is painted by hand.

Beyond measuring capabilities

We pay great attention to the processing technologies used to manufacture the molds for parts that require absolute precision, such as the lens cells. With manufacturing deviations never exceeding more than 0.002mm, the accuracy of the machines at our Aizu factory is superior even to state-of-the-art ultrahigh precision 3D measuring devices. We are committed to utmost precision during each step of the process, even beyond the reach of modern measuring capabilities.

Tactile perfection

Our quality control department ensures optimal performance and visual appearance of each of our products. But they also control for crucial qualities not easily quantified in numbers, such as the smoothness of the zoom and scaling rings. Our evaluation standards are very strict, to the point where products can be dismissed because "the ring doesn't quite feel right.